Free Impeller and Pump Design Software. An impeller is a rotating component of a centrifugal pump usually made of iron steel bronze brass aluminum or plastic.

Free Impeller And Pump Design Software Miscellaneous Caeses Forum

To analyze the internal flow and impeller deformation of the centrifugal pump the single-stage single-suction centrifugal pump titled.

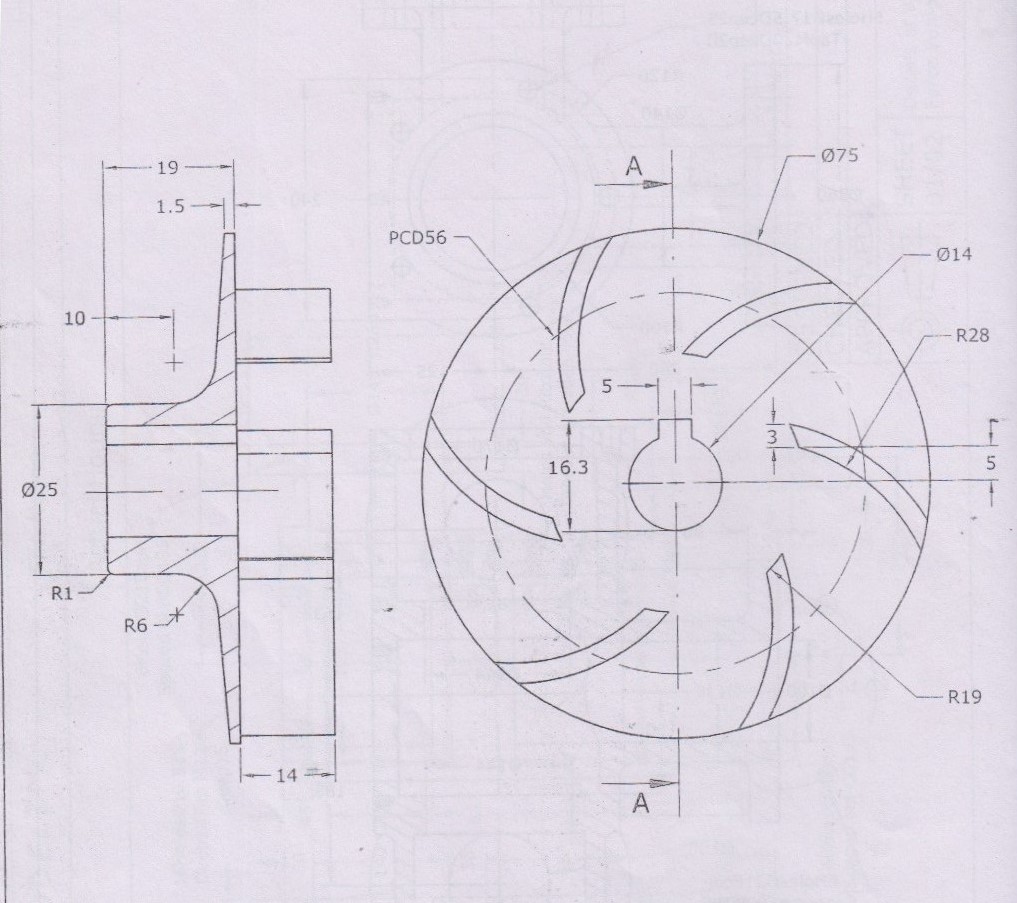

. Full PDF Package Download Full PDF Package. Geometric characteristics of impeller in the pumps. The design of impeller is made by using SOLIDWORKS software.

DESIGN AND ANALYSIS OF A CENTRIFUGAL PUMP IMPELLER USING CFD AS PER BIS NORMS. A short summary of this paper. Analysis of impeller is done by using ANSYS 120 software geometric model is imported into ANSYS software and then the full geometric model is meshed in ANSYS software.

Meshing in ANSYS CFX 120 or later. Calculation of the impeller main dimensions. Blade exit angles are 24 26 and 28.

Hub diameter suction diameter outlet width impeller diameter. The design of the impeller was carried out in order to improve the performance of a centrifugal pump. The modeling of the impeller was done by using solid modeling software CATIA V5 R18.

A Assembly of four blades B Assembly of six blades model. Blade wrap angles are 122 126 and 130. M Issa Design and Analysis of Centrifugal Pump Impeller using ANSYS FLUENT International Journal of Science Engineering and Technology Research IJSETR vol.

Safety and reliable operation is one of the most important research areas for centrifugal pump systems due to the interaction of complex flow large structural load and vibration caused by the operation of the impeller. A wide range of geometric tools and interactive charts allows users to configure the axial pumps blades easily and in a short. A project centered around a centrifugal pump has been developed that is effective in i mpressing upon freshmen the need for learning analytical tools commonly used in engineering.

Approximately 350 first term freshmen work in groups of two to design and fabricat e centrifugal pumps that they then characterize. The impeller chosen for the study was a single- entry impeller with radial vanes. Pump is singe stage single suction horizontal cantilevered centrifugal dredging pumpTobee designs and researches this new type dredging pump by making full use of advanced CAD software aiming to dredging river lake and seal which is in great need to dredge in the worldThe use of this dredge pump has remarkable comprehensive economic benefits and can meet.

The Computer-Aided Design CAD files and all associated content posted to this website are created uploaded managed and owned by third party users. The rotating of the blade is based on the natural frequency and mode shapes. To anyone who can help.

Based on numerical simulation internal flow of the centrifugal pump with. Centrifugal pump performance mainly depends upon blade exit angle. A centrifugal pump is a hydraulic flow machine in which the.

INDEX Introduction page 1 ChapterIRelationBetweenPeripheralVelocity andHead 2 ChapterIIDesign. I am looking for good authortextbook recommendation on the following. Alternative Design of Double-Suction Centrifugal Pump to Reduce the Effects of Silt Erosion.

Centrifugal Pump Impeller Design. The flow characteristics in a volute-type centrifugal pump operating at design Qd 35 m³h and off-design Qoff 20 m³h conditions are investigated using large eddy simulation. Axial Pump Profiler and Blade Design Software.

And implementation the characteristics of centrifugal pump and find out the calculations and results. The main design parameters of impeller that used for. The vibration is mainly caused by blade exit angle.

Curves for axial and radial impeller pumps Constant power consumption for a centrifugal pump is a new approach for impeller design because until today design of centrifugal pumps is focused on high efficiency performance. Defining the blade shape. Designa- p rameters from vane plane development for impeller design were selected and effect of the design parameters on.

PUMPAL is used to design the stage analyze performance refine the parameters with data reduction and model the machine according to several performance models. Design steps for radial and mixed-flow impellers. Additional challenge for this project was the application of a drum pump which is a relative small pump with an impeller.

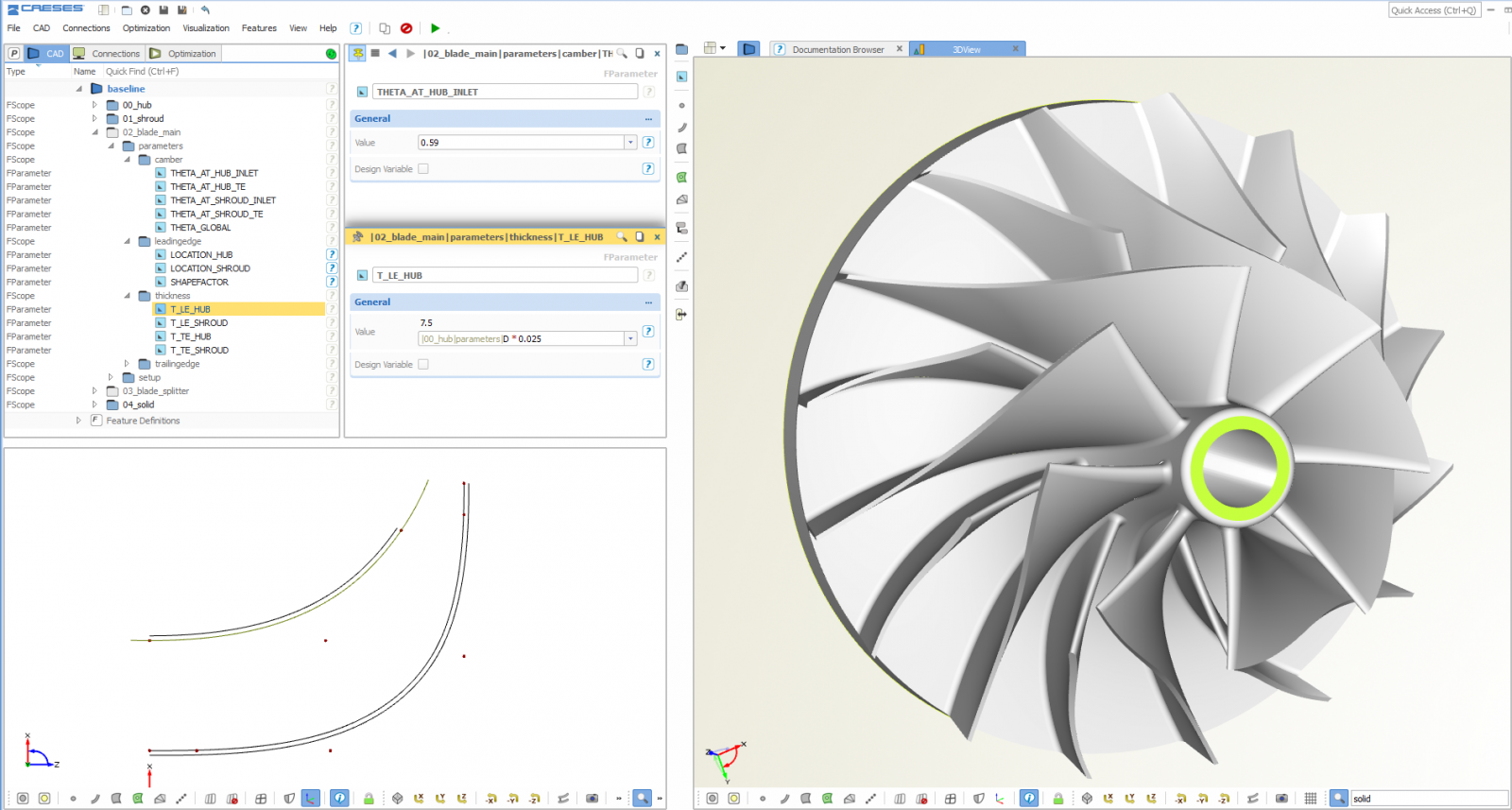

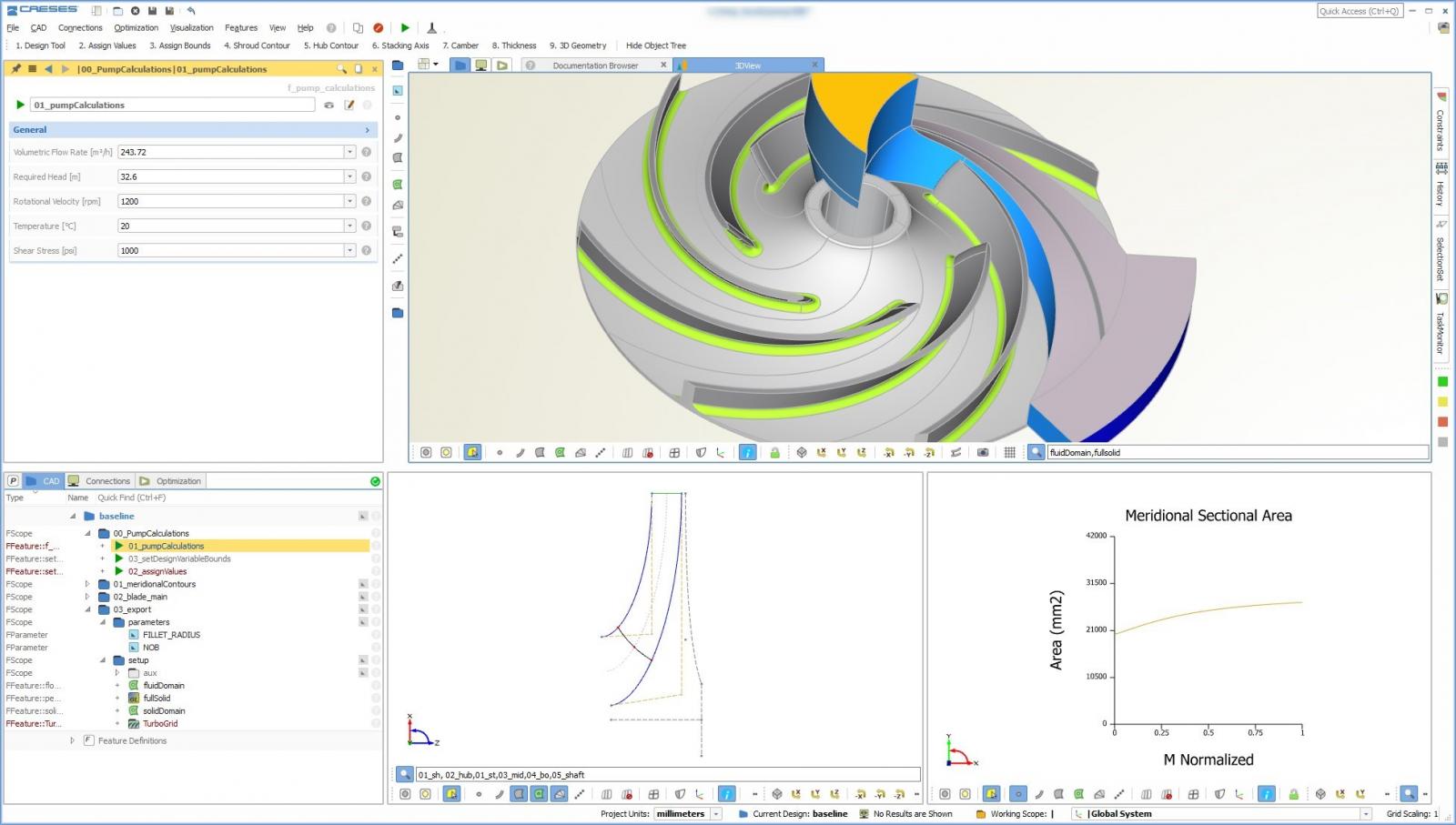

Each CAD and any associated text image or data is in no way sponsored by or affiliated with any company organization or real-world item product or good it may purport to portray. There have been several questions about impeller and pump design with CAESES which is the reason for putting together the following brief summary. It is proposed to design a blower with composite material analyze its strength and deformation using FEM software.

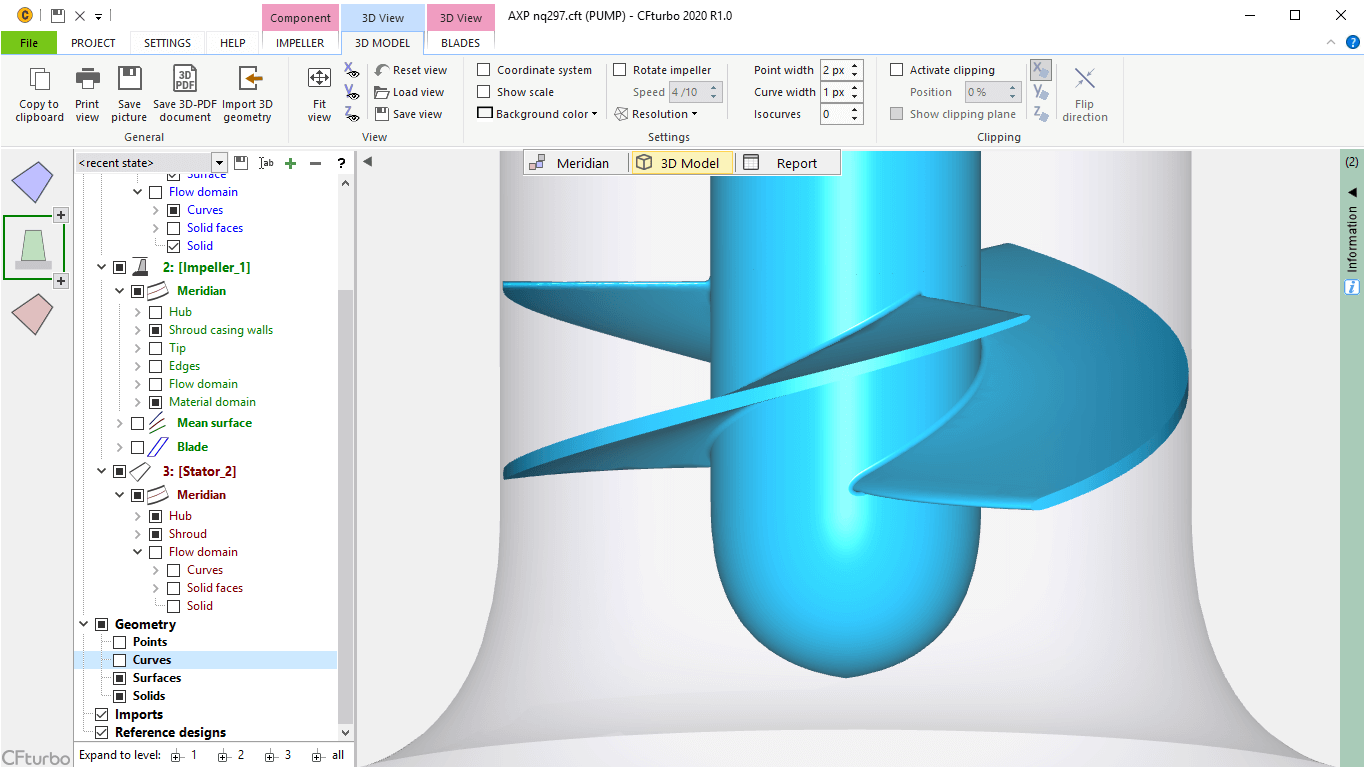

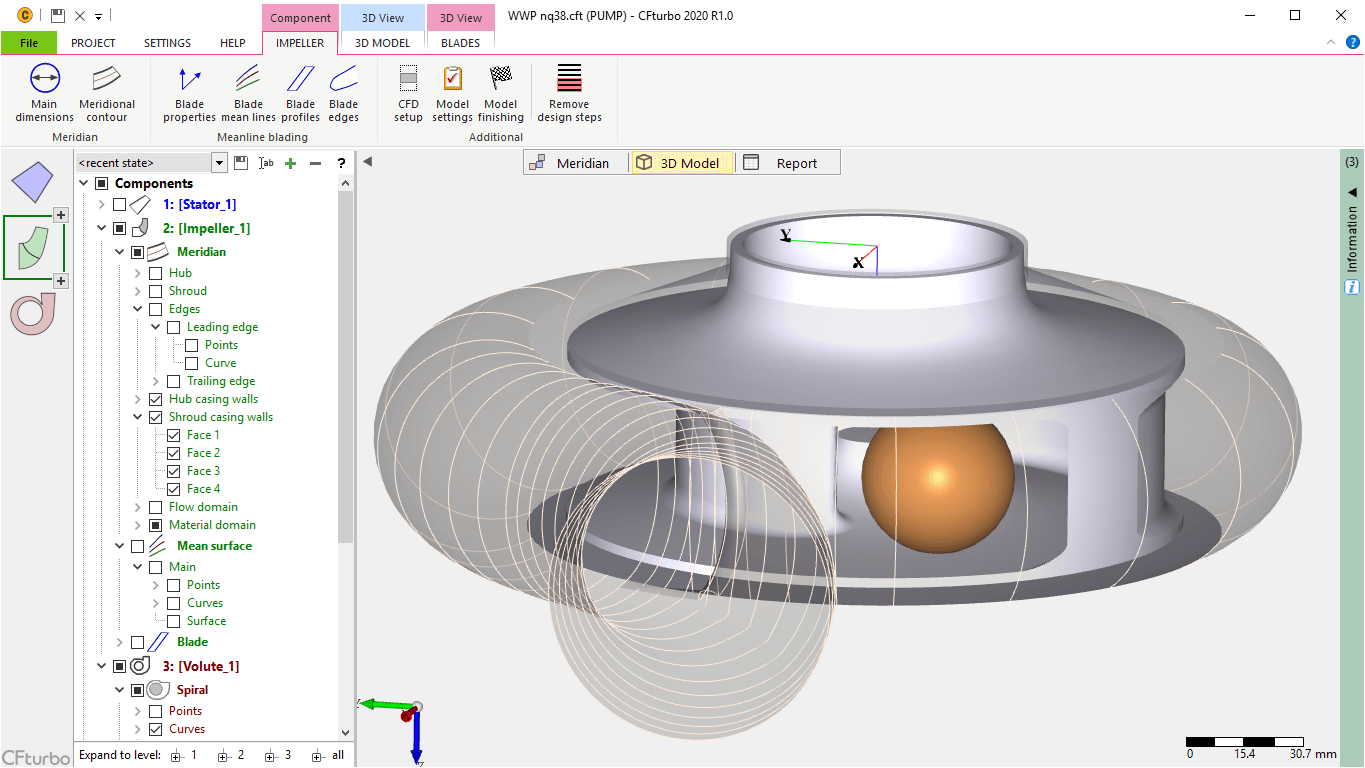

Free-form 3D free-form 2D circular arc 2D straight 2D radial element blades ruled surfaces. In recent years many modern pump design methods have been developed and with the help of some software such as TURBOdesign CFTurbo and Pcad pump design and optimal processes become simpler. BladeGen in ANSYS CFX 120 or later.

The AxSTREAM s Axial Pump Profiler and Blade Design software module is used to create and edit 3D airfoils rotors stators IGV OGV using different profiling modes including MCA DCA and more. CAESES is used by several major pump makers KSB Ebara Grundfos DMW mostly in the context of impeller and volutecasing optimization. Rgeiss Mechanical OP 18 Jan 13 1740.

CAE Software for Preliminary Design CAE Software for Axial and Radial Pumps A meanline approach is used to design centrifugal pumps and mixed-flow pumps with single and multiple stages. Containing impeller rotating shaft casing and discharge side for both models. Are varied to investigate the optimized design of the impeller of centrifugal pump.

As a fully integrated turbomachine design software platform the axstream platform provides users with the full array of centrifugal pump design software solutions whatever the incompressible working fluid water liquid oxygen liquid nitrogen mixtures organic fluids refrigerants co 2 etc across all of the crucial design stages for. Are listed in Table I. Centrifugal Pump Impeller Design.

Centrifugal Pump Design Optimization With Cfd Simscale

The Kreila Software Design Software For Radial And Mixed Pump Impellers Need Activation Software Design Activities Generative Design

Software For The Design Of Pumps

Software For The Design Of Pumps

Free Impeller And Pump Design Software Miscellaneous Caeses Forum

Centrifugal Pump Software Ciclo Software

Design Of Impeller For Centrifugal Pump Grabcad Tutorials

Cfturbo Demo On Centrifugal Pump Design And Simulation Youtube

0 comments

Post a Comment